What is the simulation technology of the cement production line?

The cement production line is a production line of cement equipment which is made up of a series of cement equipment. The process is mainly composed of breakage and prehomogenization, homogenization of raw material preparation, preheating decomposition, sintering of cement clinker, and cement grinding and packing.

The "on-site exchange meeting of the on-line simulation technology for energy saving and emission reduction of the cement industry" held by the Ministry of industry and information technology was held in Wuan, Hebei. At the meeting, Zhou Changyi, the director of the comprehensive utilization of the Ministry of industry and information, said that our country will promote the application of online simulation technology in the field of cement and other industries. It is understood that the technology has passed the technical identification of the Ministry of industry and information (Ministry of industry and information) at the end of last year.

According to reports, the online simulation technology of cement production is a fine model of all physical process according to the design parameters and characteristic parameters of operating equipment, system, through real operation of distribution control system and database into the model, so as to make the simulation system to directly obtain the running status and operation, real-time simulation of the current state of the calculation and tracking the actual operation of production line.

The system needs to be tailored to the actual conditions of the production line, such as the operation of the equipment, the status of production management, the complete equipment of the plant and so on. The implementation cycle of the whole system includes R & D, debugging, data acquisition, optimization analysis and so on. It takes more than 1 years, and different production lines have different systems. Installation of the whole system is not coherent, but each subsystem function gradually on the line, if you can let the management system or control system on-line, and then gradually make the production line into the digital control system. The application of this technology in Wuan City, Xinfeng cement limited liability company.

Reported that after the application of the technology, tons of clinker can be reduced by 8.6 kilograms of standard coal consumption, comprehensive electricity consumption of clinker per hour by 5 kilowatts, a daily production of 5000 tons of cement clinker production line with annual savings of about 15000 tons of standard coal, save electricity 8 million kwh, reduce carbon dioxide emissions of 30 thousand tons, the per ton of cement the decline in the cost of more than 10 yuan. Guangdong sub imitation technology related personnel also introduced that a production line equipped with energy-saving control system costs 2500-2800 yuan, the specific price is determined according to the actual production line, cement enterprises can recover the cost in a year or so.

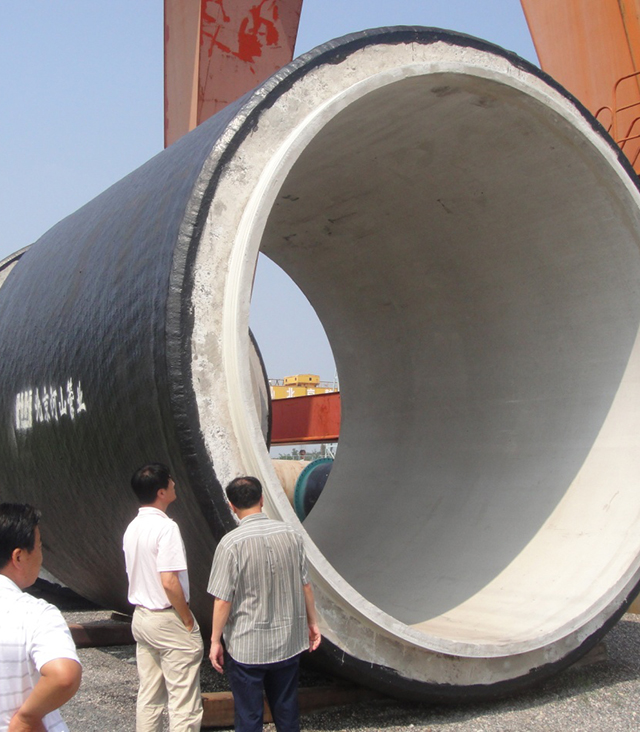

Compared with the cast in place concrete, the concrete prefabricated parts produced in the factory have many advantages.

Safety: for construction workers, the relatively stable working environment in the factory is more safe than the complex work site.

Quality: the quality and process of building components can be better controlled by mechanized production.

Speed: the standardization of the size and characteristics of the prefabricated parts can significantly speed up the installation speed and construction progress.

Cost: compared with the traditional site molding, the mould in the factory can be recycled repeatedly, and the comprehensive cost is lower. There is less demand for manual production for mechanized production. With the increase of labor cost, the cost advantage of large-scale production preform will become more obvious.

Environment: the site operation of the construction site with prefabricated parts has been reduced obviously, and the dust pollution and noise pollution have been significantly reduced.

Disadvantages of prefabricated parts:

The factory needs large yard and ancillary equipment and tools, the high cost of storage;

The construction team which needs to be trained with professional training should be fitted with the installation.

The high cost and risk of transportation, which determines the limited scope of its market radiation.